Introduction

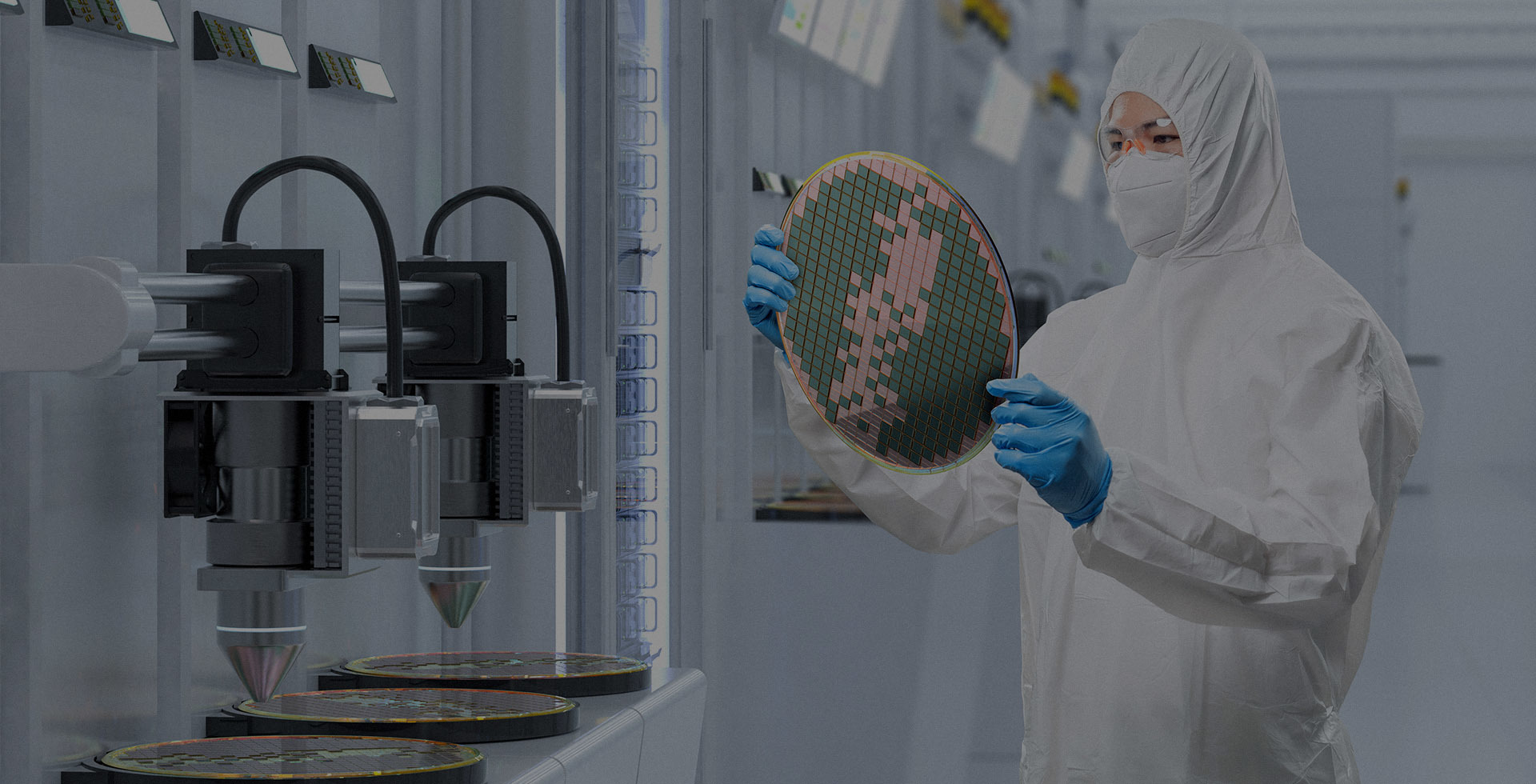

SMEI masters a number of world-leading process technologies and process modules, such as through-substrate-via, wafer bonding and deep reactive ion etching.

SMEI’s core business is MEMS process development and wafer manufacturing, holding the most advanced TSV insulation layer platform, which forms dielectric isolation area, achieves etching aspect ratio and vertical side-wall with DRIE, and shapes vias through the whole silicon wafer.

Process development

Develop product manufacturing processes

Process development business refers to the development of product manufacturing processes based on chip design solutions provided by customers. SMEI provides customized manufacturing processes.

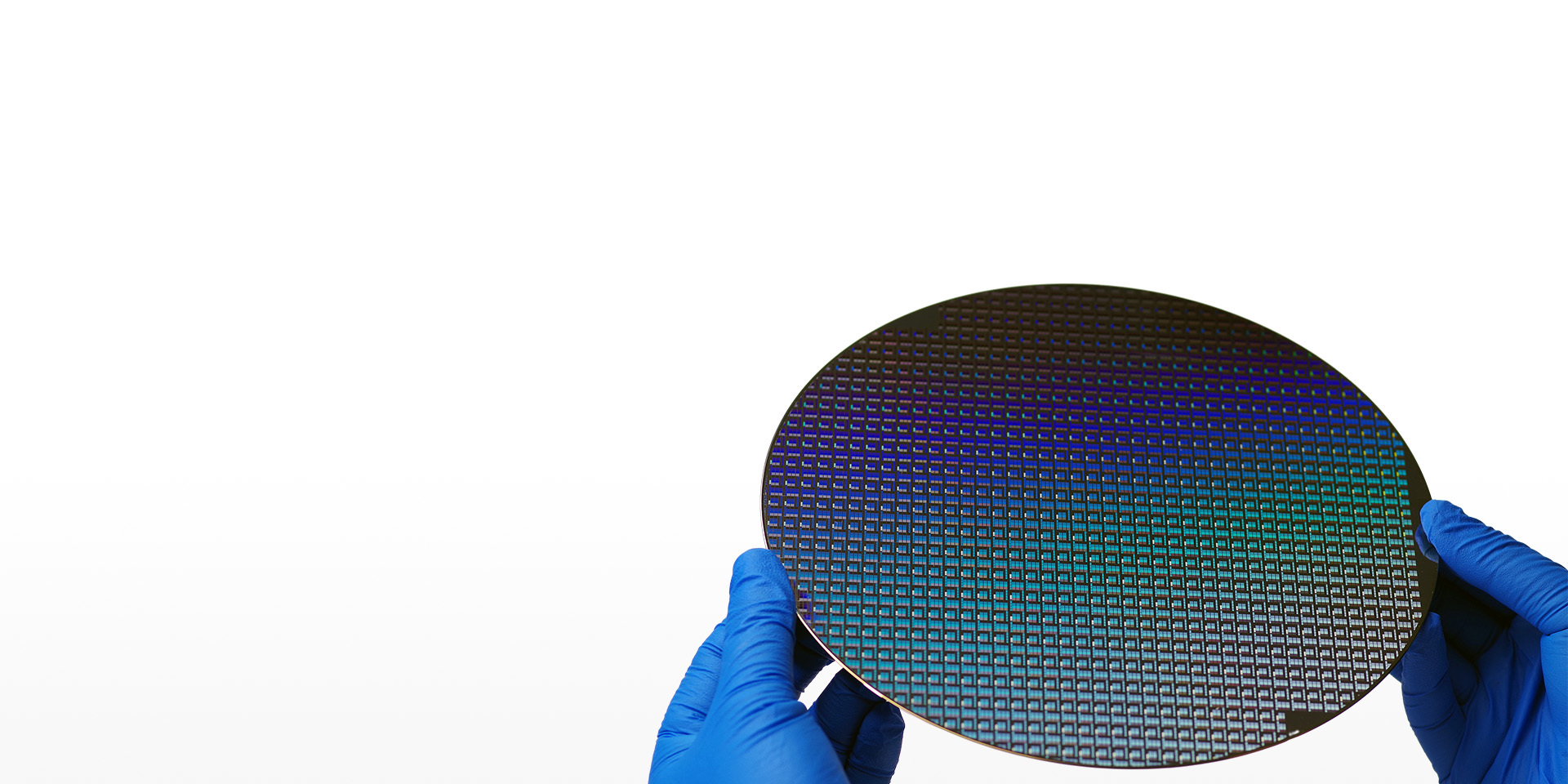

Wafer manufacturing

Provide volume production of wafers

Wafer manufacturing business refers to the volume production of wafers for customers after the development of product manufacturing processes and the solidification of product design and production processes.

Category

MEMS Microphones

Pressure and dust resistant microphones.

BAW BAW Filters

Chip that solve signal interference problems.

MEMS Pressure Sensors

Chips that detect accurate pressure changes.

MEMS Biochips

Chips that measure biological components.

MEMS IMUs

Chips that measure the velocity of objects.

MEMS Lens

A kind of lens used for lithography machines.

MEMS Micromirrors

ore devices for laser beam manipulation

MEMS OCSes

Advanced chips that switch optical circuits.

Service

Highly customized

Integrate products directly and quickly by building standardized process modules and combining with optimized key and special processes.

Quality management

Our fab has passed the ISO9001, ISO14001, ISO45001 management system certification while IATF 16949 in the certification process.

IP protection

SMEI has set up professional network firewall and software, strict data security system, and passed the ISO/IEC 27001 certification.

Integration services

SMEI is building pilot lines in Shenzhen and Huairou, and is building advanced wafer-level packaging and testing capabilities.