DRIE

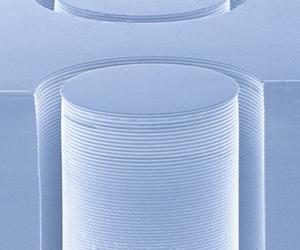

Deep Reactive ion Etching is an advanced microfabrication technology used to fabricate high aspect ratio device structures, which is mainly used in MEMS manufacturing, 3D integration of integrated circuits, advanced packaging and other fields. DRIE is based on inductively coupled plasma, characterized by anisotropic etching, selective etching, high aspect ratio, precise control, and high compatibility with integrated circuit technology.

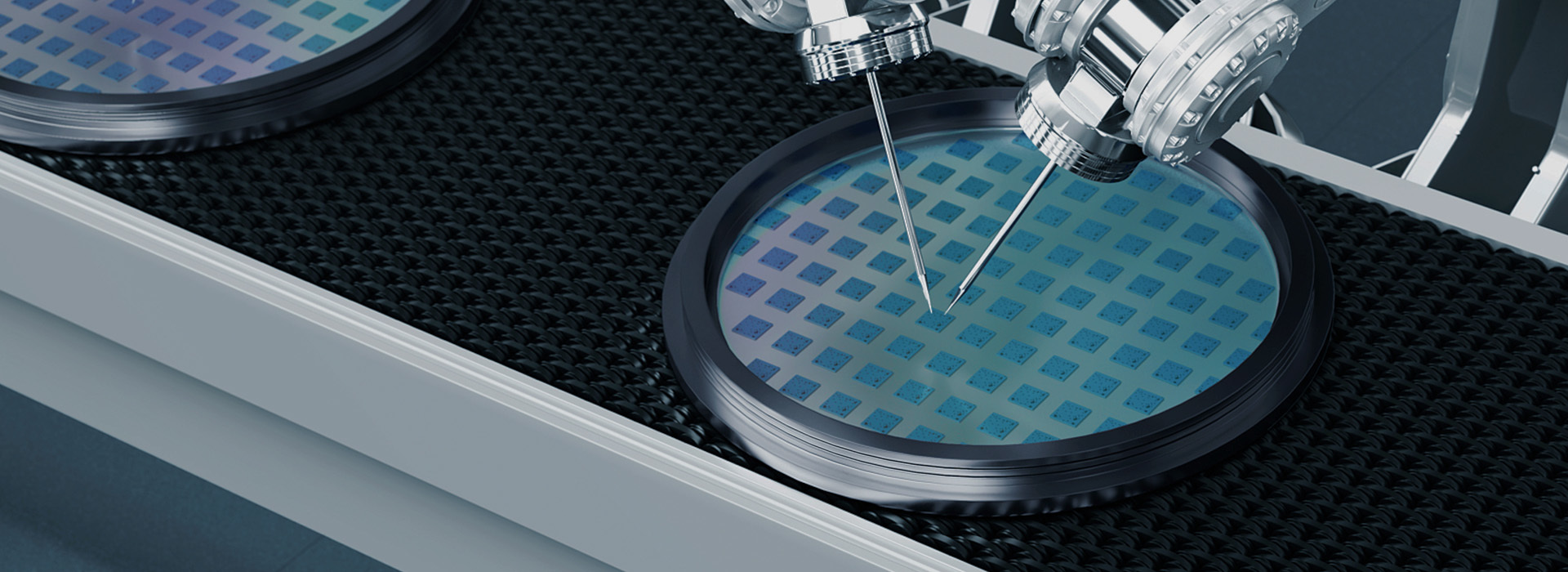

SilVia®TSV的深反应离子刻蚀过程

DRIE can be divided into Steady-State Etching and Time Multiplexed Etching depending on the etching technique. Steady state etching usually needs to be carried out under low temperature to eliminate the stop caused by by-product. Its advantage is easy to form smooth and continuous etching morphology, while the disadvantage is low etching rate, low etching selection ratio and high equipment requirements. Bosch process is the most commonly used Time Multiplexed Etching, which is based on etching and passivation alternating periodically. An etching cycle is decomposed into three processes: fluorocarbons deposition, passivation layer etching and silicon etching, to realize the depth and anisotropy of silicon etching, with the advantages of high etching rate, selection ratio, precision, vertical degree and depth to width ratio under normal temperature. Our DRIE technology is world-leading.